U-Jin: 12 t Friction Welding Machines

U-Jin Tech Corp. is a South Korean company whose friction welding machines are distributed worldwide by AluStir.

CNC 12DF-P Double Servo Motor Spindle Machine with 12 t Force

Model: CNC 12DF-P

• Rot speed: 2,000 rpm

• Force: 12 t (120 kN)

• Diameter: Ø 80 mm

• Max area: 800 mm²

• Power: 60 kW

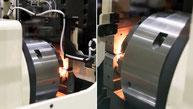

Video: CNC 12DF-P welding machine for propshafts

1:08 min. © U-Jin Tech Corp. 22 November 2017

Modern CNC control technology is used by U-Jin Tech Corp both for automatic material transport and in cases where high accuracy is required. Due to the position measuring devices known from CNC milling machines, the length tolerance of the components can be maintained more accurately than with conventional hydraulic machines. It is even possible to bring the spindle to a standstill in a given position so that the two eyes of a drive shaft can be positioned at an angle to each other.

The two spindles of these machines are driven by servo motors that allow the angular position of their motor shaft to be controlled, as well as the speed of rotation and acceleration, since they are equipped with position sensors. If the spindles are controlled in the same way as CNC-controlled servo motors, angular accuracies of ±0.5° can be achieved, e.g. at both ends of a cardan shaft.

The machine series is primarily designed for the friction welding of cardan shafts in the automotive industry, which is expressed by the letter P for propshaft.

CNC 12DF-D Double Spindle Machine with 12 t Force

This machine series is primarily designed for the friction welding of axially symmetrical drive shafts in automotive engineering, which is expressed by the letter D for driveshaft. With these components, exact length tolerances have to be maintained, but the end pieces do not have to be aligned at the a specific angle to each other.

12DF Double Spindle Machine with 12 t Force

Model: 12DF

• Rot. speed: 1800 rpm

• Force: 12 t (120 kN)

• Diameter: Ø 60 mm

• Max area: 1,100 mm²

• Power: 60 kW

Video: 12DF friction welding machine for CV joints

0:56 min. © U-Jin Tech Corp. 18 January 2017

Disclaimer

Descriptions, illustrations and numerical data may deviate from the actual design of future machines.

Further Information

AluStir has been nominated to act worldwide as sales representative of U-Jin Tech Corp. in South Korea. In close cooperation, we are able to respond to any enquiries regarding the feasibility of friction welded joints and help you with machine specifications.

We will be pleased to provide you with a quotation for a friction welding machine tailored to your needs. Please contact us by e-mail (stephan.kallee@alustir.com) or telephone (+49 6024 636 0123) if you require further information or a quotation for a machine.