U-Jin: Friction Welding Machines

U-Jin Tech Corp. is a South Korean company specialized in friction welding, whose friction welding machines are distributed worldwide by AluStir.

U-Jin Tech Corp. was founded in 2000 as a manufacturer of machine tools and assembly automation. Based on its experience in the field of machine tools, the medium-sized company has manufactured more than 130 friction welding machines since 2009. U-Jin is a leading manufacturer of friction welding machines, trusted by its customers through constant technological development and thorough quality control.

Since 2015, U-Jin has been exporting to Europe with CE certification, and in December 2016 in won an export order worth 10 million US Dollars. The research centre associated with U-Jin has the

objective to develop new products to deliver innovative products.

U-Jin has initially developed and manufactured hydraulic friction welding machines, and it built Korea's first CNC friction welding machine in 2012. The rapid growth is based on the development

of technologies that meet the needs of its customers. U-jin's top priority in these rapidly changing times is: "The greatest value lies in passion for technology."

Friction welding machines

U-Jin's friction welding machines are manufactured in South Korea. They are

of the highest quality and have one or two movable spindle heads each. They are used commercially in many places for welding cylindrical parts of all types.

AluStir, in cooperation with U-Jin, is able to carry out feasibility studies or contract manufacturing for you. For large quantities, we can advise you on machine specifications and machine

procurement as well as on quality assurance.

Actuation concepts

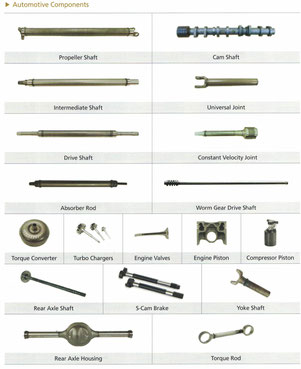

Friction welded products

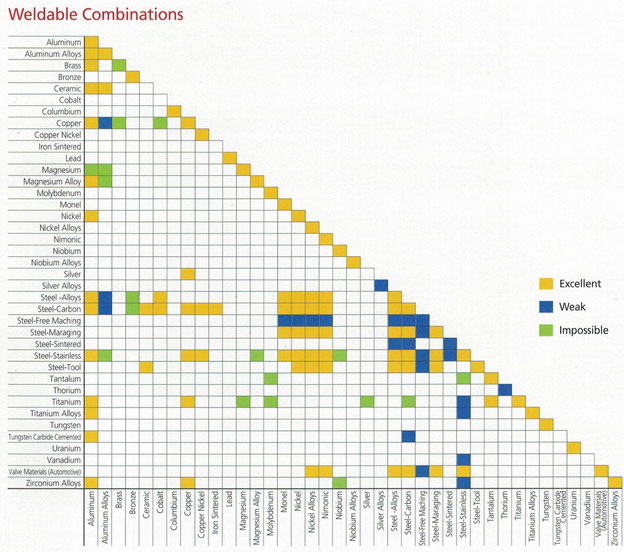

As friction welding operates below the melting point of the materials, even dissimilar material joints can be produced with high tensile strength. In many cases, the tensile strength of the bimetallic joint is higher than that of the softer base material.

U-Jin's friction welding machines are used industrially for a wide variety of products:

- Gear shafts made of chrome-molybdenum steel

- Electric terminals and cable lugs made of pure copper and pure aluminium

- Long screws and bolts made of structural or high-speed steel

- Stainless steel and aluminium adapters for refrigerants or coolants in superconductors

- Shaft-hub connections in hollow shafts for the drive train of cars

- Carbon steel (Advanced High Strength Steel, AHSS) and stainless steel pump shafts

- Transition pieces in carbon steel S25C and stainless steel SUS304 (tensile strength 443 N/mm²)

- Transition pieces made of carbon steel S45C and stainless steel SUS304 (tensile strength 639 N/mm²)

- Motor shafts made of structural and stainless steel

Friction welded components produced on U-Jin machines

Materials

Company history of U-Jin Tech Corp.

- 2009:

-

- February: Foundation of U-JIN Tech Corp.

- 2010:

-

- June: ISO 9001:2008 Certification

- August: Venture Business Certification

- November: Foundation of the company's own research institute (KOITA)

- 2012:

-

- July: Green Technology Certification

- September: Small and Medium Company Technological Innovation Award

- December: Excellent Award in manufacturing and technology of the Gyeonggi-do Green Industry Awards (Governor of Gyeonggi-do).

- 2013:

-

- October: Designated as promising KmU in Gyeonggi

- December: Promising export company (MSS Gyeonggi)

- 2015:

-

- October: Recognition for Development of Excellent Capital Goods (MOTIE)

- November: Receipt of the European CE Certificate

- 2016:

-

- January: Certificate of the product-specific approved exporter

- December: Designation as Talents Raising Medium Company

- December: $ 10 million Export Tower on Trade Day

- 2018:

-

- October: Exhibitor at the MSV Engineering Fair in Brno

- 2019:

-

- September: Exhibitor at EMO trade fair in Hanover

Friction welding machines of U-Jin

Weblinks

Disclaimer

Descriptions, illustrations and numerical data may deviate from the actual design of future machines. The weldability of different dissimilar material joints is strongly dependent on the alloy and has to be confirmed in case by case through feasibility studies and parameter optimisation studies.

Further information

AluStir has been nominated to act worldwide as sales representative of U-Jin Tech Corp. in South Korea. In close cooperation, we are able to respond to any enquiries regarding the feasibility of friction welded joints and help you with machine specifications.

We will be pleased to provide you with a quotation for a friction welding machine tailored to your needs. Please contact us by e-mail (stephan.kallee@alustir.com) or telephone (+49 6024 636 0123) if you require further information or a quotation for a machine.