The Wuppertal Schwebebahn is a 13.3 km (8 mi) long suspended monorail in Wuppertal, Germany. It was inaugurated in 1901 and is temporarily running just on weekends, but every-day service is scheduled from August 2021. Its 15th generation rolling stock is friction stir welded and in regular use since 18 December 2016.[1]

One of the most ambitious applications of friction stir welding of railway rolling stock is welding the aluminium car bodies of the Wuppertal suspension railway according to DIN EN 15085-2 and ISO 25239.[2][3][4][5] The FSW process has been developed by HAI in Ranshofen Austria into a key strategic technology since commissioning the first FSW machine in October 2005.

The current generation of monorail electric multiple units (Gelenktriebwagen, GTW) is commonly called "WSW GTW Generation 15" but also known as "GTW 2014". [4][5][6]

They are manufactured by the Düsseldorf based company Vossloh Kiepe and have been in use since 2016 to replace the previous suspension railways of the type GTW 72 .

From a technical point of view, Generation 15 is a new development. A particular innovation is the use of three-phase asynchronous motors with the option of energy recovery during braking. The electronic equipment of the suspension railway has been fundamentally changed, and the European Train Control System ETCS is being installed. The exterior design of the new suspension railways is based on the GTW 72, while the interior design has been specially revised.[8][9][10][17]

Procurement

In May 2010, an order for the creation of a design concept was awarded to the Berlin designer office büro + staubach, [18] which is known for having done the exterior design for the Düsseldorf NF10 and NF8U tramcars and for the Variobahn vehicles in Munich, Graz, Potsdam and Nuremberg. [20] The design and the specifications were presented in September 2010.[18][21] On 10 November 2011, a contract was signed with Vossloh Kiepe for 31 new vehicles; the order volume is 122 million Euros.

Development

Railway rolling stock has normally to be designed according to existing standards and regulations. However, some the conventional standards cannot be applied to suspension railways. The technology of the new Wuppertal suspension railway is based on the tram construction and operating regulations (BOStrab), but many points had to be adapted. For this purpose, WSW employees were involved in the development process and numerous measurements were taken on the existing GTW 72 vehicles, i.e, the previous generation.

The driving behavior when the vehicle is empty and fully occupied was examined and the angle of inclination and the forces at sensitive points such as the joints measured. Also measurements of the noise emissionswere carried out in order to obtain reference values for the new development.[17]

The course of the entire route of the Wuppertal suspension railway was modeled on the computer and the driving behavior of the new vehicles on this route was calculated. Scenarios such as towing or a collision of suspension railways were examined using simulation software.[8][17]

Manufacture

The trains are developed and manufactured under the leadership of Vossloh Kiepe, with the Prose AG engineering office at Winterthur being commissioned to develop the bogies and the Munich branch of Prose and design & technik from Altenrhein on Lake Constance for the development of the car bodies.[17][25]

The aluminium car bodies are manufactured in Austria at Hammerer Aluminum Industries from friction stir welded aluminium extrusions. The front and rear cabins at the Leichtbau-Zenrtum in Saxony .[25][26] The gearboxes are developed and supplied from ZF Friedrichshafen. [11]

The joints at the car transitions were supplied by ATG Autotechnik at Siek in Schleswig-Holstein , the bellows from PEI at Bologna. [27] The devices of the train control systems were developed by Alstom Transport Germany [28] and manufactured in Belgium. [19]

The final assembly of the components into the car body takes place in the Vossloh Rail Vehicles plant in Valencia, [12]Tests on the stationary vehicle are also carried out there. [7] The suspension railways are then dismantled again into the individual assemblies, transported to Wuppertal and reassembled and put on the rails in the main workshop of the Wuppertal suspension railway in Vohwinkel.[17][25]

In December 2013, the first car body of an end car was completed,[26] meanwhile more car bodies have been produced.[17] In early 2015, the first car body was equipped with windows and painted in Valencia.[8][30]

Transport and Commissioning

The vehicles were transported by semi-trailers from Valencia to Wuppertal. The time of delivery of the first vehicle to Wuppertal had to be re-scheduled from October 2015 to 14 November 2015. [21] [20] [4] Around 5000 people came to the unveiling of the first part of the wagon on a semi-trailer.[22] Mayor Andreas Mucke was also present and gave a speech.[33][34]

On the night of 9 February 2016, the first test drive was conducted by a train on its own, initially without passengers. The section between the Vohwinkel and Hammerstein was driven several times, emergency braking was carried out and the angle of inclination was tested. Car 01 was used, which was temporarily equipped with measuring devices for this purpose. According to the Wuppertaler Stadtwerke, these first tests went smoothly.[35][36]

WSW mobil publicly announced the location and route section of the nocturnal test drive, so that around 100 onlookers attended.[36] In the first three days of testing, 200 kilometers were covered.[37] While the test drives initially took place at night, from the end of April 2016 tests also took place during the day and thus in parallel to the ongoing operation of the GTW 72 vehicles.[38]

The regular operations commenced on 18 December 2016 after completing the test phase of the vehicle and the train control system, approval by the technical supervisory authority in Düsseldorf.[38] At that time, seven of the 31 suspension railway trains ordered had been delivered.

The training of the operating personnel began even before the first test drive with the real vehicle. For this purpose, a simulation software was developed in which the arrangement of the control elements of generation 15 and the route of the Wuppertal suspension railway were reproduced.[39]

Initially, the new vehicles went into operation without any major technical problems. In mid-May 2017, eleven new vehicles were already in operation and two more were already in Wuppertal. On 19 May 2017, however, between the Pestalozzistrasse and Westende stations, a component of the chassis came into contact with the scaffolding of the suspension railway. The Generation 15 vehicle was traveling at a speed of around 50 to 60 km/h (31 to 37 mph) at that time. The property damage to the route and vehicle was minor, but the cause of the scaffold contact was not known. Therefore the delivery of new vehicles was put on hold and the speed limit was reduced to 40 km/h (25 mph). [40] Seven additional minutes were required for each run due to the lower speed, which led to a reduction in the operation frequency due to the limited number of vehicles.

After more than a year of troubleshooting, the WSW announced in August 2018 that a design change would be carried out in order to be able to rule out renewed contact with the scaffolding in the future. The speed was temporarily reduced to 30 km/h (19 mph) until the design change could be implemented, but the delivery of new vehicles could now be continued.[41]

On November 18, 2018, the conductor rail of the suspension railway detached itself from the scaffolding over a length of several 100 meters and fell into the Wupper River. Thereupon the passenger service of the suspension railway was stopped for several months. According to the WSW, the incident was not caused by the vehicles' pantographs, as they have a predetermined breaking point.[42] The delivery of Generation 15 vehicles was therefore continued unchanged, and acceptance runs and test runs of the train control system were carried out.[43]

In January 2019, it was planned to have put all new vehicles into operation at the time of resumption of passenger operations.[8][44]

Technical Details

Electric Drive

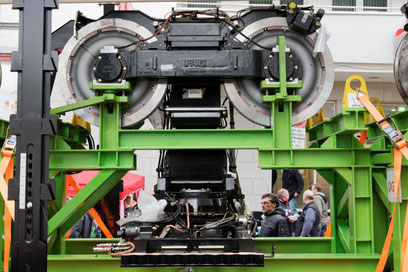

Three-phase asynchronous motors are used in the bogies.[45] Each bogie has a drive motor to which ZF helical-bevel gears are connected on both sides.[17][45] The first gear stage consists of a bevel gear, the second of a spur gear. Due to the three-phase AC technology, the travel speed is changed by varying the frequency in the stator windings.

Thus the gearbox has a fixed ratio of 12.4127. The transmission technology for each bogie weighs 280 kg plus about 50 kg to take-in and take-off clutch. There are 7.5 liters oil in a gearbox. The seal on the shafts have labyrinth seals, that run without contact and therefore do neither generate friction nor a notch effect. The engine and transmission are fully suspended and mounted in rubber elements that reduce vibrations and noise emissions. The housings are made of aluminum .[11][17] The cooling fins on the motor are clearly visible from the outside .

Electrically, the drive is divided into two drive groups: Current collectors are installed at the first and last car, which take the DC from a third rail through a power converter to the two traction motors each. If one drive group fails, the vehicle can continue its journey with the remaining drive group at half power and reduced top speed.[17]

The top speed of these trains is 65 km/h (40 mph), although the Wuppertal suspension railway is only approved for only 60 km/h (37 mph).[45] The operating voltage was increased from 600 volts to 750 volts. This and the use of three-phase motors increases the maximum acceleration to 1.3 m/s².[17] Thus, the average acceleration triples in compaerison to the GTW 72.[45] This means that the minimum cycle time can be reduced from three to two minutes and the travel time for the entire route can be reduced by 5 to 25 minutes.[8][46]

Brakes

The rail vehicles have two independent brake systems: the electromotive brake and the mechanical brake. With the electromotive brake, the three-phase motor acts as a generator; the kinetic energy of the suspension railway is converted into electrical energy and the vehicle is braked. The generator output corresponds to the engine output; the braking deceleration is also the same as the maximum achievable acceleration. For a trip between two stations, the WSW estimate the electrical energy required to be two kilowatt hours, with one kilowatt hour being recovered by the electric brake with each braking process before the next station.[45]

The mechanical braking system consists of four brake calipers, each located on the rear wheel of a bogie. When the brake is actuated, the brake calipers press brake pads onto the side surfaces of the wheels with the aid of hydraulic cylinders (hydraulic brake).

There are two valves on the hydraulic unit: an emergency brake valve , which releases the full brake pressure, and a proportional valve , via which the brake pressure can be adjusted with an electrical control unit.[17]

In normal operation, only the electromotive brake is used; the hydraulic brake is used for forced braking , rapid braking and emergency braking. Both braking systems are independent of the voltage applied to the conductor rail and function in the same way in the event of a power failure.[17]

Car Body

In order to achieve the lowest possible vehicle mass, the car body was made of lightweight construction and is made entirely of aluminum.[17] The weight of the car body, together with the front and rear cabins, is 5.4 tons.[25] The individual components are first assembled to assemblies using friction stir welding. These assemblies are then connected to one another using conventional metal inert gas welding. Due to the small permissible manufacturing tolerances, the welding sequence is fixed.[17]

Previously, time-consuming tests had to be carried out to check the weld seams, during which parts of the interior fittings also had to be removed. The trains of this new generation have, therefore, representative reference weld seams in critical, but easily accessible places, which save checking the other weld seams.[8][17]

Electronics

There are two independent data bus systems in the new suspension railway cars . A system connects the control units of the safety-relevant components such as drive, brakes and doors. The other devices such as air conditioning or passenger information systems are connected to the second system . The CANopen bus system is used for data transmission.[8][17]

Train Control

The new wagons of the Wuppertal suspension railway are equipped with ETCS equipment for ETCS Level 2+.[28][47][48] Here, the communication between train and track equipment takes place via Eurobalises and train radio.

Accordingly, the trains have a Eurobalise antenna and a train radio system for Terrestrial Trunked Radio, which is used in Wuppertal instead of GSM-R . Various odometry sensors are used to determine the current position and speed, which are stored by a trip recorder. The ETCS vehicle computer (EVC) processes all data, monitors the movement of the train and, if necessary, carries out train control. The driver can access the ETCS system via the Driver Machine Interface (DMI) monitor installed in the driver's cab . The technical supplier is Alstom Transport Germany from Salzgitter . The on-board ETCS system continuously transmits the current position of the vehicle to the track equipment and the signal box . The previous route blocks will be retained.[48]

Exterior Design

The exterior design of the vehicles was created before the tender. During the design of the vehicle, the basic dimensions of the previous generation had to be retained. The reasons for this are the clearance profile of the route, dimensions and markings in the stations, weight specifications and small curve radii of 9 m in the turning loops.[17][45][49]

However, some changes compared to the previous vehicles have been made: the front window is now inclined downwards to allow the driver a better view, the rear window extends from the roof of the car almost to the ground and offers a panoramic view for the passengers, and adjacent windows have been added connected to each other to create the impression of a "ribbon window".[50] The designers stated that when designing the landmark of the city of Wuppertal, continuity was in the foreground and a timeless, not a fashionable, design [49]

The installation of further glass elements was not possible, as glass windows are heavier than aluminum side walls and the weight specifications could otherwise not have been met.[39] The original plans included plastic cladding for the chassis, but this was later discarded because it would have increased the weight and due to requests from the public for a clear view of the technology.[24][22]

Generation 15 trains are painted light blue to blend-in with the WSW's corporate design.[14] The color is lighter than the blue used on WSW mobil buses.[51] Unlike before, there are no full advertisements placed on the monorail rolling stock. Only the underside of the vehicle and the middle section between the two joints and the associated window are approved for advertising.[8][52]

Interior Design

The seat layout of the passenger compartment has remained the same compared to the GTW 72; On the left side of the vehicle there are two seats next to each other in the direction of travel, on the right side there are the entrance doors and a passage.[43] Instead of plastic seats, upholstered, wooden seats are used, which have a width of 47.5 cm (18¾ in).[54]

Multipurpose compartments are installed at the ends of the train; the front door also has a folding ramp for wheelchair users. There are additional handles on the seats and on the ceiling.[53] The passenger information system consists of two monitors, one of which is placed directly behind the driver's cab and one in the middle of the suspended monorail railcar.[45] There are seven surveillance cameras in each train. The images of these are recorded and displayed in the driver's cab.[44]

For the color scheme, three different variants were developed, each of which is used on a third of the vehicles. The side walls are always white and the handrails are gray, but the non-slip floor and seat cushions are green, red or yellow, depending on the variant. [24][54] Of the 31 trains ordered, eleven received a green, ten a yellow and ten a red interior design.[55] The ceiling is made of sheet metal with integrated LEDs; the entrances are separately lit and equipped with electronic passenger counters.[54]

The temperature inside the vehicle is regulated by an air treatment system with a dehumidifier. However, the maximum cooling capacity is limited, as there is little space available for air conditioning on the roof of the vehicle.[17] The windows can still be opened.[56]

The driver's seat is height adjustable and has suspension. A transparent plexiglass (perspex) partition with a built-in door is located between the passenger compartment and the driver's cab.[17][53] Two touchscreens are installed in the driver's desk.[53] The driver's cab has an air conditioning unit that is independent of that of the passenger compartment.[8][17]

Operation

A new type of double-flange wheels, which is made from just one part instead of being assembled from tyres on rims is causing some problems on the new generation of suspended monorail vehicles in Wuppertal. Notches, material breakouts and material accumulations are causing problems on the wheels, and as a consequence some rails surface defects have been generated, when the damaged wheels are contacting the rails like like permanent hammer blows. In addition door malfunctions, software problems, inadequate bonding, problems with the air conditioning have to be resolved. Therefore, the Wuppertal suspension monorais is temporarily running just on weekends, but every-day service is scheduled August 2021.[59]

Other FSW Applications at HAI

HAI uses FSW also for welding automotive components such as a B-pillar for the Audi R8 Spyder and a battery base for electric cars.[4][5] In the manufacture of a range extender rotary piston engine from a powder metallurgically produced aluminium alloy, friction stir welding made it possible to use a joining process that both avoids the gaps in the running area of the sealing elements and enables a defect-free weld seam with properties similar to those of the base material.[6][7]

Rail Modelling

In September 2015, the Wuppertaler Stadtwerke announced that they would be selling a model of the new suspension railway generation in nominal size H0 in their customer centers from November 2015 .[19] The models are made by the company Herpa and were produced in an edition of 7500 pieces.[57]

In addition to the standard version, there was a "Special Edition" limited to 1000 copies at the start of sales, which shows a route map with all the stops on the underside and the lettering "VohwinkelElberfeldBarmenOberbarmen" on the side, which is composed of the city districts passed through without separators. In addition, the WSW sell another special model "blue wonder" with a batch size of 2000 pieces.[58]

References

- Wikpedia article about Frank Ellermann on the German

Wikipedia by NearEMPTiness (97,4 %), Onkelkoeln, Aka, Invisigoth67, Nordprinz, GünniX et al.

-

Certificate DIN EN 15085-2 Certification Level CL1.

- F. Ellermann, S. Pommer, G. Barth: Einsatz des Rührreibschweißens bei der Fertigung der Wagenkästen für die Schwebebahn Wuppertal. DVS

Congress: Große Schweißtechnische Tagung, 15/16 September, Hotel Pullman Berlin Schweizerhof, Berlin.

- Dr.-Ing. Frank Ellermann, Ranshofen, Österreich Rührreibschweißen (FSW) von Aluminiumkomponenten für den Schienenfahrzeugbau. In: Schweißtechnische Lehr- und Versuchsanstalt Halle

GmbH: Fügen und Konstruieren im Schienenfahrzeugbau. Vorträge der 11. Fachtagung

„Fügen und Konstruieren im Schienenfahrzeugbau“ in Halle on 5 and 6 May 2015.

- Frank Ellermann: Fertigung von Aluminiumschweißkomponenten für die Automobilindustrie. In: Schweiß- und Prüftechnik

09-10/2018, p. 143–144.

- A. Elrefaey, K. Anders, H. Kilian, F. Ellermann und W. Kühlein: Friction Stir Welding of Extruded Powder Metallurgy Al

Alloy. Friction stir welding was used successfully to join an extruded powder metallurgy Al alloy without discontinuities, voids, or defects. Welding Journal 2014, p. 451-457-s.

- Johann Blaha, Michael Steinbauer, Christian Seltenhammer, Peter Schäffler, Kevin Anders, Helmut Killian, Rudolf Gradinger, Josef Reiter, Wolfgang Kühlein, Frank Ellermann, Claudia Weithaler,

Tim Dommert, Karl Auer: Innovative Herstellmethoden für Bauteile eines Range Extender

Kreiskolbenmotors. In: Energieeffiziente Mobilität: Chancen der Werkstoff- und Prozesstechnologie, Ranshofener Leichtmetalltage, 7. LKR-Verlag, Ranshofen; 2012, p. 172–184.

- Wikpedia article about WSW GTW Generation 15 on the German Wikipedia by EveryPicture (85,1 %), Crazy1880 (3,7 %), Atamari (1,3 %), Rainald62 (1,2 %), Wikimatze (1 %)

et al. Retrieved on 18 December 2020.

- Wikpedia article about Wuppertaler

Schwebebahn on the German Wikipedia by Firobuz (18,7 %), Djuenger (12,1 %), Stefan17675 (7,8 %), Every Picture (7,3 %), Rote4132

(4,6 %) et al. Retrieved on 18 December 2020.

- Wikpedia article about WSW mobil on the German Wikipedia

by SkiFreak99 (54,5 %), Peterbeier--6655 (12,1 %), Schumir (4,7 %) et al. Retrieved on 18

December 2020.

- ZF Friedrichshafen: Wuppertaler Schwebebahn: Mit

ZF hoch hinaus (flyer).

-

↑ Die

Wuppertaler Schwebebahn: Daten & Fakten. In: WSW AG. Retrieved on 13 September 2019.

-

↑ SCHWEBEBAHN, GTW 2014 WUPPERTAL, DEUTSCHLAND (PDF). In: Kiepe Electric. Retrieved on13 September 2019.

-

↑ Hochspringen

nach:a b Erste

neue Schwebebahn wird angeliefert. auf neue-schwebebahn.de. Published on 23. Oktober 2015. Retrieved on 14 November 2015.

-

↑ Stadt

Wuppertal – Erste neue Schwebebahn kommt nach Wuppertal. In: www.wuppertal.de. Retrieved on 15 November 2015.

-

↑ Wuppertal : Erster neuer Schwebebahn-Wagen kommt per Tieflader. In: RP ONLINE. Retrieved on 15 November

2015.

-

↑ Hochspringen

nach:a b c d e f g h i j k l m n o p q r s t u v Joachim Ebmeyer and Christoph Deiss: Schweizer Drehgestell-Knowhow für neue Schwebebahnwagen für die Wuppertaler

Stadtwerke. In: Eisenbahntechnische Rundschau 9/2014, p. 177–181.

-

↑ Hochspringen

nach:a b c Zeitstrahl. auf neue-schwebebahn.de. Retrieved on 2 November 2014.

-

↑ Hochspringen

nach:a b Ein

Top-Modell für Wuppertal. Website der Wuppertaler Stadtwerke. Retrieved on 13 September 2015.

-

↑ Büro+Staubach Transport auf buero-staubach.de. Retrieved on 2 November 2014.

-

↑ Design

Exterior und Interior auf neue-schwebebahn.de. Published on 1 September 2010. Retrieved on 2 November 2014.

-

↑ Hochspringen

nach:a b c Vossloh Kiepe baut neue Schwebebahn-Generation auf neue-schwebebahn.de. Published on 10. November 2011. Retrieved on 2 November 2014.

-

↑ Stefan Melneczuk: Schwebebahn 2015: Die erste ist aus Holz. Website der Westdeutschen Zeitung. Published on 20 April 2012. Retrieved on 15 November 2014.

-

↑ Hochspringen

nach:a b c d Jetzt

kommt Farbe ins Spiel auf neue-schwebebahn.de. Published on 22. Februar 2013 Retrieved on 2 November 2014.

-

↑ Hochspringen

nach:a b c d Noch

einige Stationen bis Wuppertal auf neue-schwebebahn.de. Retrieved on 2 November 2014.

-

↑ Hochspringen

nach:a b Erster

Wagenkasten der neuen Generationat neue-schwebebahn.de, 21. November 2013. Retrieved on 2 November 2014.

-

↑ Faltblatt von ATG Autotechnik zum Wagenübergang.

-

↑ Hochspringen

nach:a b Peer Jacobsen: Tradition und Zukunft: Die Wuppertaler

Schwebebahn mit ETCS Level 3 und TETRA. In: Eisenbahntechnische Rundschau 6/2014, p. 54–57.

-

↑ Erste

neue Schwebebahn für Wuppertal auf busundbahn.de. Published on 25. November 2015. Retrieved on 28 November 2015.

-

↑ Hochspringen

nach:a b Fertigung in Valencia auf neue-schwebebahn.de. Retrieved on 19 February 2015.

-

↑ Lothar Leuschen: Neue

Schwebebahn kommt später. Website des Solinger Tageblatts. Published on 1 September 2014. Retrieved on 22 January 2018.

-

↑ Erster

Teil der neuen Schwebebahnen angekommen. Website der Rheinischen Post. Published on 14. November 2015. Retrieved on 15.November 2015.

-

↑ Wuppertal begrüßt die neue Schwebebahn. Website der Westdeutschen Zeitung. Published on 14 November 2015. Retrieved on 15 November 2015.

-

↑ Erster

Wagen in Vohwinkel – Die neue Schwebebahn ist da. Website der Rheinischen Post. Published on 14 November 2015. Retrieved on 15. November 2015.

-

↑ Erste

Testfahrt der neuen Schwebebahn: Wuppertaler Stadtwerke. In: www.wsw-online.de. Archived from the originalon 15 February 2016. Retrieved

on 15 February 2016.

-

↑ Hochspringen

nach:a b Stadt

Wuppertal – Neue Schwebebahn absolviert Jungfernfahrt ohne Probleme. In: www.wuppertal.de. Retrieved on 15 February

2016.

-

↑ Manuel Praest: Per

Schwebebahn-Simulator durch Wuppertal. In: Westdeutsche Zeitung. Retrieved on 15 February 2016.

-

↑ Hochspringen

nach:a b Am 23.

April fährt die Schwebebahn erstmals tagsüber. In: Westdeutsche Zeitung. Retrieved on 30 March 2016.

-

↑ WSW

testen neue Schwebebahn im Fahrbetrieb: Wuppertaler Stadtwerke. In: www.wsw-online.de. Retrieved on 4 February 2016.

-

↑ Westdeutsche Zeitung: Austausch der alten Schwebebahn-Wagen stockt weiter. Retrieved on 3 January 2019.

-

↑ Wuppertaler Schwebebahnen müssen langsamer fahren. Published on 13 August 2018. Retrieved on 3 January 2019.

-

↑ Ursache für Schwebebahn-Unfall in Wuppertal unklar. Published on 19 November 2018, Retrieved on 3 January 2019.

-

↑ Wuppertaler Schwebebahn: Testfahrten laufen. Published on 7 December 2018. Retrieved on 3 January 2019.

-

↑ Schwebebahn-Neustart in hellblau - Wuppertal total: Aktuelle Nachrichten und lokale News. Retrieved on 3 January 2019.

-

↑ Hochspringen

nach:a b c d e f g Konstruktion auf neue-schwebebahn.de. Retrieved on 3 November 2014.

-

↑ ausschreibungen-deutschland.de: Planung, Bau, Lieferung und Inbetriebnahme eines Betriebssystems (Zugsicherung / Zuglenkung) für die Wuppertaler Schwebebahn. Published on 13 July 2012.

-

↑ Betriebssystem auf neue-schwebebahn.de. Retrieved on 4 November 2014.

-

↑ Hochspringen

nach:a b Mike Bent: First Schwebebahn Generation 15 Cars

Delivered. In: Railvolution 6/2015, p. 68–69.

-

↑ Hochspringen

nach:a b c Die Schwebebahn ist eine einmalige Chance auf neue-schwebebahn.de, Published on 9 November 2010 Retrieved on 3 November 2014.

-

↑ Außendesign auf neue-schwebebahn.de. Retrieved on 3 November 2014.

-

↑ Stefan Melneczuk: Die

neue Schwebebahn fährt hellblau in die Zukunft. Website der Westdeutschen Zeitung, Published on 22 February 2013. Retrieved on 15 November 2014.

-

↑ Außenwerbung auf neue-schwebebahn.de. Retrieved on 3 November 2014.

-

↑ Hochspringen

nach:a b c d Innendesign auf neue-schwebebahn.de,. Retrieved on 4 November 2014.

-

↑ Hochspringen

nach:a b c d Stefan Melneczuk: Schwebebahn 2015: Mehr Platz, mehr Licht, mehr Sicherheit. Website der Westdeutschen Zeitung, Published on 22 February 2013, Retrieved on 15 November 2014.

-

↑ Tausende feiern neue Schwebebahn: Wuppertaler Stadtwerke. In: www.wsw-online.de. Retrieved on 16. November

2015.

-

↑ Klima,

Heizung und Komfort auf neue-schwebebahn.de, Published on 21 December 2014. Retrieved on 19. February 2015.

-

↑ Die

neue Schwebebahn im Modell ‹ Neue Wagen für die Schwebebahn. Retrieved on 3 January 2018.

-

↑ Schwebebahn Sondermodell 'Blaues Wunder' - Wuppertal Shop. Retrieved on 3 January 2018.

-

Peter Thomas: Nach 120 Jahren Pause in

Wuppertal. Frankfurter Allgemeine Zeitung, FAZ. Updated on 27 July. 2020. Retrieved on 18 December 2020.

The text of this web page is available under the Creative Commons Attribution-ShareAlike 3.0 Unported License (CC BY-SA 3.0). The licenses of each photo will be displayed by clicking onto the photo.