FSW: Artemis III Orion

Friction Stir Welding of the Orion-Spacecraft for NASA's Artemis III Program to the Moon

The first friction stir weld of the Orion spacecraft to the moon was completed in January 2021 at NASA's Michoud Assembly Facility

At NASA's Michoud Assembly Facility in New Orleans, technicians from Orion prime contractor Lockheed Martin have welded together three cone-shaped parts of the Orion crew module for the Artemis III mission using the friction stir welding process that will land the first woman and the next man on the moon.

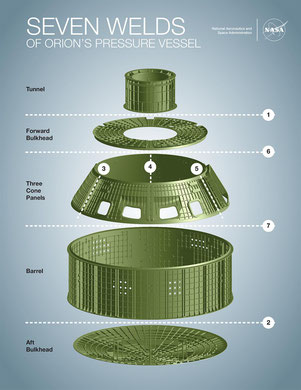

The crew module's pressure vessel, consists of seven aluminium alloy parts machined on a high-speed milling machine and welded together using the FSW process. The pressure vessel is designed to withstand the harsh and demanding environment of deep space and is the core structure into which all other elements of the Orion crew module are integrated.[1][2]

After welding is completed on the crew module's cone panels - one of which contains windows through which astronauts can see the Moon and Earth - work will begin to join the forward bulkhead to the tunnel to form the top of the spacecraft, followed by joining the fuselage and aft bulkhead to form the bottom of Orion.

Lastly, the forward bulkhead is welded to the top of the panels, and the seventh and final weld will join the bottom of the cone panels to the tube to complete the pressure vessel. Once welding is complete on the primary structure of the Artemis III crew module, it will be transported to NASA's Kennedy Space Center in Florida for further assembly beginning this autumn.

Orion, the Space Launch System and the Exploration Ground Systems programme are fundamental elements of the Artemis programme. Artemis I will be the first integrated flight test of Orion and SLS and is scheduled to launch later this year. Artemis II will follow and will be the first crewed mission to take humans further into space than ever before.[1][2]

Lockheed Martin technicians completed the first friction stir welds on the Orion spacecraft at NASA's Michoud Assembly Facility in New Orleans in January 2021

References

- Rachel Kraft: Welding Underway on Orion for First Artemis Mission Landing Astronauts

on the Moon. 26 January 2021.

- Barbara Zelon: The first weld on the Artemis III Orion Spacecraft was completed at NASA’s

Michoud Assembly Facility.

- Rick Amrose: Our Lockheed Martin technicians have completed the first stage of welding panels for the capsule of NASA - National Aeronautics and Space Administration's Orion crew module. 26 January 2021.