Inventor of welding plaques for the forge welding of iron and steel

Jules Laffitte (1830-1902) was a French engineer who around 1879 invented the welding plaques named after him. These were used for the forge welding of iron and steel ("Les plaques de M. J. Laffitte a souder des fers et des aciers").

For this purpose, he fixed molten borax onto a metal wire mesh as a support that was stiff enough and did not hinder the welding process, but in a way even favored it.

The first plaques were delivered to the trade in 1879.

J. Lafitte: Étude sur le soudage des fers et des aciers. Les plaques à souder

© Jules Laffitte, 1894

Subject of the Invention

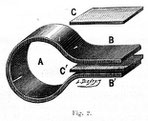

In principle, Jules Laffitte's welding plaques consisted of a loosely woven wire or steel mesh, which was coated on both sides with a layer of molten borax, the mesh serving as a carrier. The result was a rigid plaque two to three millimeters thick that could easily be cut into slices by hand or with a pair of tin snips.

J. Lafitte: Étude sur le soudage des fers et des aciers. Les plaques à souder

© Jules Laffitte, 1894

According to their inventor, the wire mesh in Jules Laffitte's plaques played a triple role:

1) It served as a carrier for the molten borax, which allows this substance to be used in perfect and regularly

determined amounts.

2) It gave the panel sufficient rigidity so that it could be pushed between workpieces of all

kinds

3) It served as metallic cement between the parts to be welded: the metallic threads were embedded in the

softened workpieces and contributed a lot to the connection to ensure that the welded products are characterized.

Double and triple support plaques were prepared for thicker parts , i.e. the plaques were made from two or three wire meshes embedded in the molten borax. This type of support could also be used for wire mesh with wires with a larger or smaller diameter, as required. This made it possible to adapt the thickness of the plaque to the dimensions of the parts to be welded.

Research and Development

Jules Laffitte used , among other things, thicker or thinner wire grids and looser or narrower mesh panels of all sizes. He used his ingenuity to improve his plaques with great enthusiasm, in order to fulfill all the wishes of the practitioners who placed their trust in him. The mechanically produced plaques were perfectly regular and always had the same dimensions, which made clean packaging possible.

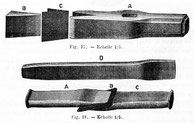

In order to show that the weld seams produced in this way were beyond any doubt and absolutely safe, a number of tests were carried out, which were reported with sketches and explanations. Most of the experiments were carried out on steel. However, experiments were also carried out in which iron was welded onto steel or vice versa.

Awards

In 1881, Jules Laffitte exhibited his invention in Tours and was awarded a silver medal. In 1882, he was awarded a gold medal in Bordeaux after numerous tests that were carried out in the presence of a specially created jury.

The jury awarded the welding

plaques an honorary diploma at the marine exhibition in Rochefort. In 1885, after experiments carried out in the presence of the jury chaired

by Paul Bert, the

plaques at the Exposition du Travail in Paris were awarded an honorary diploma. Finally, they were awarded a silver medal at the World

Exhibition in Paris in 1889, at which Jules Laffitte carried out many interesting experiments in front of the visitors, the success of which contributed significantly to the spread of the welding

plaques.

In addition to these awards, Jules Laffitte was pleased to see his welding process spread to the most distant

countries: his

plaques were shipped to all countries.

Tomb

His tomb is still preserved on the Cimetière du Père-Lachaise, the largest cemetery in Paris (Division 91, grave number C.A.P. N ° 191-1902):