The First Welded Aluminium Bridge in the World

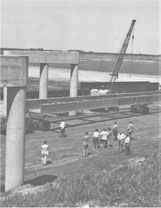

The first welded aluminium bridge in the world: 86th Street Overpass, spanning Interstate 35 and 80 at Northwest Eighty-sixth Street, Urbandale, Polk County, Iowa. West side of overpass. View to southeast.

Library of Congress, HAER IA-42-8

The 67 m (220 feet) long and 11 m (36 feet) wide overpass at 86th Street, which spans Interstates 35 and 80 at Northwest Eighty-Sixth Street in Urbandale, a suburb of Des Moines in Polk County,

Iowa, was built in 1958 as

the world's first welded aluminum bridge. It played an important part in the development of America's Interstate Highway System.[1]

Due to the long delivery times for steel in the late 1950s, aluminium was favoured, although it was said to have five disadvantages that could only be compensated for by an aluminium-specific

design:

- High cost

- Difficulties in production

- Lack of stiffness

- Drastic thermal expansion and shrinkage and

- More expensive and complex than a comparable concrete construction[1]

Typical beam - lateral bracing bolted connection, view to northeast

Typical beam - lateral bracing welded connection, view to northeast

Beam bearing shoe and abutment, view to northwest.

The design details of the overpass at 86th Street, which was built as a welded aluminium structure, influenced later bridges. It was designed by the well-known engineer Ned Ashton from Iowa on behalf of the Iowa State Highway Commission in the post-war period when steel was still scarce for bridge construction. The successful combination of the use of structural aluminum and arc welding was unprecedented for aluminum bridges at that time. Never before has a structure combined such novel materials and techniques as this overpass in Urbandale.[1]

Detail of spandrel beam, showing typical welds and deck underside. View to southwest.

Library of Congress, HAER IA-42-14

Fabrication

The bridge was manufactured by the Pullman Standard Car Manufacturing Company, Chicago, Ilinois.[1]

The beams and all their components such as web plates, flanges, nuts and bolts were made of 5083-H113 aluminium welded with 5083 filler wire.[2]

After several weeks of testing various arc welding machines, rods and wires, the welding instructions were adopted at a meeting in April 1958 by Ned Ashton and approximately 16 representatives of

Pullman, Alcoa, Reynolds and Kaiser. The design team agreed on using 5083 welding wire with a diameter of 1.6 mm (1/16 inch) and a gas consisting of 75% helium and 25% argon.[1]

The 3.65 m (12 feet) wide and 28,95-38.40 (95-126) feet long subassemblies were fabricated at the Pullman Standard Car Manufacturing Company’s plant in Chicago

Iowa Department of Transportation Library, Ames, IA

Transport

Each subassembly required three railroad cars to be transported by rail to the nearest railroad station

Iowa Department of Transportation Library, Ames, Iowa

Road transport to the construction site

Iowa DoT Library

The entire bridge was divided into four large subassemblies of 12 feet wide and 95 to 126 feet long. From 27 June to 3 July 1958, the bridge components were loaded onto a total of twelve

articulated railway cars, each 20 meters (65.5 feet) long, and transported by rail from Chicago to Rider, a small-town train station two miles from the bridge site. Once in Rider, the components

were transported on specially designed trucks for the rest of the route. Two 10-ton cranes were needed to lift the segments into place.[1]

Erection

The bridge was erected and built by Jensen Construction Co. and United Contractors, Des Moines, Iowa.

Iowa Department of Transportation Library, Ames, Iowa

Convetional conrete deck

Iowa DoT Library, Ames, IA

The completed Bridge awaiting its inauguration

Iowa DoT Library, Ames, IA

The construction of the bridge required 35 t (77,000 lbs) of aluminium as well as a large amount of conventional materials. The substructure and deck slab contained approximately 36 t (80,000 lbs) of reinforcing steel and over 400 cubic meters of concrete. During fabrication, 31,964 cubic feet of gas and 588 kg (1,297 lbs) of 2-ounce welding wire were used to produce a total of almost 3800 m (12,500 feet) long welds. After the investment of effort and materials, the bridge was finally opened to traffic on Wednesday, 24 September 1958, when Joanne MacDonald, the 1958 Miss Iowa, ceremonially cut a ribbon made of aluminum foil.[1][4]

Aluminium fell out of favour with civil engineers after steel prices fell, making the 86th Street overpass a technical anomaly. The light metal never caught on to bridge construction, but the 86th Street Overpass remains an important milestone in the history of civil engineering: the world's first welded aluminium bridge.[1]

South portal of overpass and 86th Street. View to north.

Disassembly and Replacement

The aluminium bridge of Iowa eventually became a victim of progress. Although it had served well for 35 years, the bridge was too small for the busy 86th Street hub and was replaced in 1994.

The last inspection reports for the bridge in the 1980s and early 1990s documented that some cracks had formed in the welds. However, these were not caused by fatigue in the structure

itself.

Several indentations on the underside of the support structure had been caused by excessive loads that scratched the underside of the bridge. Such notches, if unnoticed, could have developed into

cracks and further damaged the structure. They were therefore carefully ground out whenever they occurred.[3]

A thorough field and laboratory research programme was carried out on the aluminium supports when they were removed. Both tensile and fatigue tests were performed on representative components of

the beams. In all cases, the test results showed that even after about 40 years of operation, the aluminium components still had tensile strength and fatigue fracture properties comparable

to those when the bridge was first erected and in line with what would be expected for new bridges today.[2][5][6]

Although the aluminium structure was in good condition when it was removed in 1993, this could not be said for the concrete deck, which had deteriorated considerably over time.[7]

Lage: 41.652111, -93.736421

© Google Maps

References and Further Information

- Clayton B. Fraser and John J. Roberts: 86th Street Overpass, spanning Interstate 35 and 80 at Northwest Eighty-sixth Street, Urbandale, Polk

County, Iowa. Loveland, Colorado, May 1994.

-

Subodh K. Das und J. Gilbert Kaufman: Aluminum alloys for bridges and bridge decks.

TMS, 2007.

- Joseph M. Isenberg: Iowa Highway Research Board: 1949–1999.

- Michael Wieskamp: 1958 - 86th Street bridge over I35/80. For many years there was no interchange there. It was surrounded by

farms.

- R. E. Abendroth, W. W. Sanders und V. Mahadevan: A Continuous Span Aluminum Girder Concrete Deck Bridge - Part 1 of

2: Field Test Performance and Evaluation, 1996. Juli 1996.

http://publications.iowa.gov/id/eprint/21800

- R. E. Abendroth, W. W. Sanders und S. Hansz: A Continuous Span Aluminum Girder Concrete Deck Bridge - Part 2 of 2: Fatigue Tests of Aluminium Girders, 1997. May

1997.

- Google Street View.